Troublemaker pop-up top

Written by am

Of all things in and on our vehicle, the pop-up roof strained our nerves the most. We lost sleep over it. In the course of the modification of the car, we left no stone unturned to mitigate the situation a bit.

About 100 kg of weight, a complicated mechanism with a rack inside, gas pressure springs that did not work where they should and a tent fabric that was not waterproof. This is the best way to describe our pop-up top.

The two gas pressure springs on the outside proved to be useless for lifting up the top.

The two gas pressure springs on the outside proved to be useless for lifting up the top.Only the fact with the high weight was already apparent at the time of purchase. Back then, we assumed that one of the four gas pressure springs might be broken. Two of them were installed on the outside (right over the driver’s and co-driver’s doors) and other two - longer and stronger ones - were mounted inside the G. In fact, we found out that the two gas springs on the outside had no effect on the roof at all, hence, we removed them.

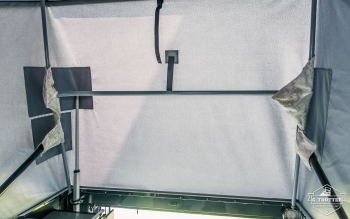

The two long gas pressure springs in the interior differ from most pop-up top constructions as they do not directly act on the roof, but on a rack. It turned out that one of the springs was broken and we replaced it with a new one. However, it did not bring alleviation.

Some help is needed

In search of an expedient, we came across electrical linear actuators. The installation of such a linear actuator facilitates the opening of the roof by pushing it up 40 cm. It is indeed a relief that this has not to be done by human hands anymore. Before we installed the liner actuator, it required an incredible exertion (using both hands and with the aid of the head and the back) to lift the roof to a certain height. Only beyond that dead center position the gas pressure springs start to be effective and facilitate the opening of the pop-up top.

Not less exhausting or less dangerous, is the closing of the roof. To make the roof collapse, a hearty jolt on the inside rack is required. This demands a loth of physical strength, since you need to cope with the force of two gas pressure springs (each 75 kg). If you succeed, the next (and worst) step is to hold the entire roof for a few seconds on your head and then bend your knees to slowly place it on the linear actuator. While the roof is then moving downwards, you need to take care that the tent goes inside. What unfortunately is and was in our case not easy. Somehow there is always some fabric hanging out on the sides and a second person is required to stuff the fabric inside.

Rain inside the G

In addition to all the difficulties of opening and closing, the pop-up top had another surprise ready for us. After the first heavy rain, it turned out that the tent fabric of the pop-up top was not water-proof. The water ran into the interior and the tears down the cheek. We were speechless.

The pop-up top received a new tent fabric.

The pop-up top received a new tent fabric.After a miserable attempt of impregnating the tent and after we cast away the idea of sewing some kind of "shower cap" for the G, we had to face the music: a new fabric is uinevitable. Vendors who have experience with pop-up tops are quite rare in Austria. In the end, however, we found a one-man company, whose owner did not only provide valuable advice but also did a great job in changing the tent fabric. Our tent is now waterproof and changed its color from orange to grey.

A nasty shock

"There is a hole" - a sentence you definitely do not want to hear, especially if the person is pointing to the recently renewed tent fabric of your pop-up top. Unfortunately, despite the utmost care, a few weeks after successful replacement of the tent fabric, the joints of the rack had torn three small holes into the fabric. Tears again. This time even a bit more.

After the first shock, we decided to stop the whining. By then, we had been so involved with this car that there was no way back. Things happen. Holes happen. Actions are to be taken. The first action was to seal the holes (done with "Ramsauer"). Second, we had to find a solution to prevent further holes caused by the joints. Thus, we sewed little hoods around the joints to avoid any contact with the fabric.

No end of trouble

All's well that ends well? The existing roof construction is not ideal, despite the tools we are now applying to facilitate its handling. Not to say that it’s still a sword of Damocles hanging over our heads. Every opening and closing of the roof is a safety risk, with which we have to live and travel until further notice. Perhaps we will have the whole construction changed after the trip (and after a lottery win). Until then, we look envious to all the overlanders of this world whose pop-up top can be opened with the effort from a fingertip.